|

|

| Home | Blogs | Solargon | More Links | Workshops | Innovation |

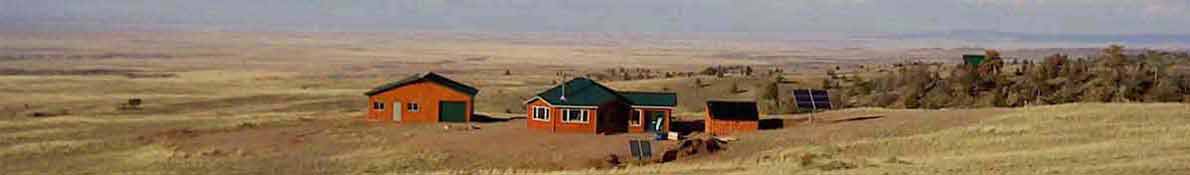

With the help of Guffey Windmill (see previous page), we ordered two Sharp monocrystalline 175 Watt solar panels. These panels have been around for a while, and are known to be reliable in the hard (high wind) conditions we experience at this site. Guffey installed the steel pole near the well, and we installed the rack (a very solid top-of-pole mount from Power Fab, also known as DPW) and the panels, did the wiring (the above ground part), and tested the pump. In the pic at right, the panels have been mounted, but the controller is "loose wired" and sitting on the ground; you can also see the well head. The excavation is the end of the trench that leads from the well about 90 feet to the cabin utility vestibule, off to the right. The well casing has a pitless adapter intalled at 5 feet depth, and the water line runs underground to the tank in the vestibule. We connected a hose to the indoor end of the line using SharkBite adapters, and ran the hose outside again (you can see it in this view) to test the well pum

With the help of Guffey Windmill (see previous page), we ordered two Sharp monocrystalline 175 Watt solar panels. These panels have been around for a while, and are known to be reliable in the hard (high wind) conditions we experience at this site. Guffey installed the steel pole near the well, and we installed the rack (a very solid top-of-pole mount from Power Fab, also known as DPW) and the panels, did the wiring (the above ground part), and tested the pump. In the pic at right, the panels have been mounted, but the controller is "loose wired" and sitting on the ground; you can also see the well head. The excavation is the end of the trench that leads from the well about 90 feet to the cabin utility vestibule, off to the right. The well casing has a pitless adapter intalled at 5 feet depth, and the water line runs underground to the tank in the vestibule. We connected a hose to the indoor end of the line using SharkBite adapters, and ran the hose outside again (you can see it in this view) to test the well pum p.

p.

In the picture at right, you can see the result - water! Nice, cold, clear water! Details - the pump was set 280 feet below the surface, with nearly 300 feet of empty well below it. Because the static water level is about 20 below the surface, there is little danger of running dry with anywhere between 2 and 5 gallons per minute flow into the wellbore from fractures in the granite. We consider the bottom half of the well to be essentially a pipe from the deepest water sources to the pump placement, and allows for settling-out of the sediment that we know enters the wellbore during spring snowmelt. We ran the pump for several days with no problem simply to do a water exchange because the well had been treated with chlorine when it was completed. We've drunk the water with no problems at this point!

After the test, we finished up the "hard" wiring, making the solar panel wiring and ground all neat, tidy, and code compliant! PIctured at right, I am finishing wiring in the protective box that we installed to keep the controller in. The controller is rated for outdoor installation by itself, but we liked having the protective cover in our harsh environment. This also provides a convenient means to connect conduit from the well, from the cabin (float controller wire), and to the solar panels.

Click here for the spec sheet for the specific panels we used in this application. While the wind load ratings are similar to other panels, these modules have a structural bar midway down the long axis that to my mind increases their strength. They've been up for a while now, and not blown away in any of our blizzards!